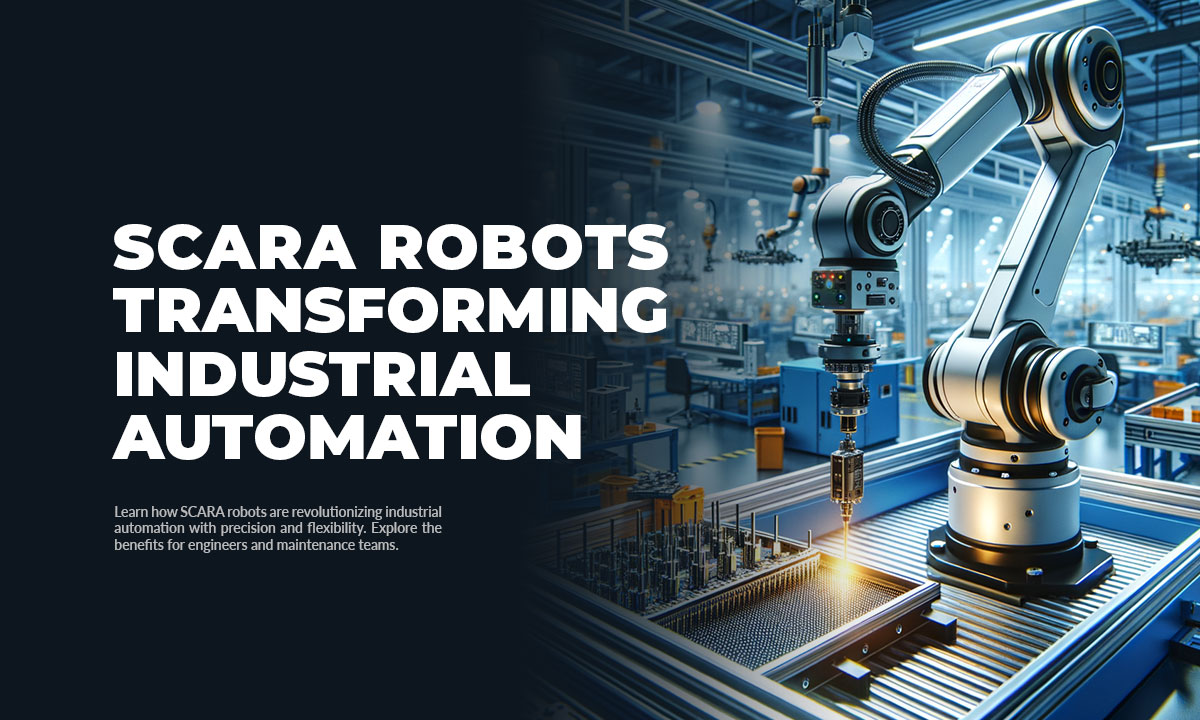

SCARA robots, which stands for Selective Compliance Assembly Robot Arm, are a popular choice in industrial automation processes due to their speed, precision, and flexibility. These robots are designed to perform repetitive tasks with high levels of accuracy, making them invaluable assets in various industries including automotive, electronics, and consumer goods manufacturing.

Introduction to SCARA Robots

With their unique arm structure and compact footprint, SCARA robots are capable of performing tasks such as assembly, pick-and-place, packaging, and machine tending with remarkable efficiency. Their ability to operate in confined spaces while maintaining high speed and precision makes them reliable solutions for streamlining production lines and optimizing manufacturing processes. For more information on industrial automation, explore SIENERJI's automation solutions.

Understanding SCARA Robot Technology

SCARA robots are characterized by their horizontal arm with rotational joints at the base and elbow, allowing for precise and smooth movement in the X-Y plane. This design enables the robots to reach across large work areas while maintaining accuracy and consistency in their operations.

Equipped with advanced control systems and high-performance end-effectors, SCARA robots can handle a wide range of payloads and perform complex tasks with ease. These robots are often integrated with vision systems and sensors to enhance their capabilities in identifying, sorting, and handling various components and products.

Furthermore, the intuitive programming interfaces and software solutions available for SCARA robots empower operators and engineers to effortlessly configure and adapt the robots to new production requirements, thereby facilitating rapid deployment and reconfiguration for different tasks. Learn more about the future of automation by reading our blog post on the impact of industry robots on manufacturing efficiency.

Overall, the combination of mechanical precision, advanced control technology, and user-friendly programming makes SCARA robots indispensable in modern industrial automation, offering a potent combination of speed, accuracy, and versatility for a diverse array of manufacturing applications.

Advantages of SCARA Robots in Industrial Automation

The advent of SCARA (Selective Compliance Assembly Robot Arm) robots has revolutionized the industrial automation landscape. SCARA robots are revered for their exceptional speed and agility, but this is just the tip of the iceberg concerning their manifold advantages. Let's dive into how these sophisticated machines offer a quantum leap in operational efficiency.

One of the most distinguishable features of SCARA robots is their selective compliance, which allows for controlled flexibility in specific directions. This feature is pivotal when it comes to tasks requiring delicate handling, such as assembling small electronics. The arm is rigid in the Z-axis, ensuring stability for consistent pick-and-place operations, yet offers compliance in the XY plane. This combination epitomizes precision that manual labor can seldom match.

The compact and streamlined design of SCARA robots equates to a smaller footprint within industrial settings. Unlike their larger counterparts, they can be seamlessly integrated into existing production lines without the need for extensive reconfigurations. This design efficiency is conducive to space conservation and can engender significant cost savings regarding factory layout and optimization.

SCARA robots come with a tailor-made design for high-speed automation tasks. They can perform at a remarkable pace, thereby amplifying productivity and throughput. In comparison to manual labor, SCARA robots can operate continuously without succumbing to fatigue, thus maintaining consistent output quality throughout prolonged production cycles.

Moreover, these robots excel in repeatability. They can execute an operation with the same precision over and over, ensuring uniformity in mass production scenarios. This attribute is critical in fields where precision is non-negotiable, like in the pharmaceutical and electronics industries.

Explore the full potential of industrial automation by learning about automation products for industrial applications in our blog post.

Lastly, SCARA robots are highly adaptable and can be easily programmed for a wide range of applications. The incorporation of advanced sensor technologies and vision systems further enhances their versatility. They are capable of performing more complex tasks by adjusting in real-time to accommodate different types of products or materials, positioning SIENERJI at the forefront of delivering cutting-edge solutions.

Applications of SCARA Robots in Different Industries

The industry applications for SCARA robots transcend traditional manufacturing environments, extending their influence across a myriad of sectors, thereby showcasing their remarkable versatility.

In the automotive industry, SCARA robots are indispensable for their precision and speed. They are utilized for assembly tasks, such as fitting circuit boards within control units and precisely placing gaskets. The high repeatability and accuracy of SCARA robots help maintain the integrity and safety standards demanded by this sector.

Electronics manufacturing reaps the benefits of SCARA robots perhaps more than any other industry. The assembly of delicate components such as capacitors, connectors, and switches demands the dexterity that these robots provide. They ensure components are placed correctly without damage, a task that is challenging and time-consuming for human workers, thereby reducing production time and increasing efficiency. Here, the robots contribute to the miniaturization trend by handling increasingly smaller components with impeccable precision.

Pharmaceutical companies have turned to SCARA robots for their ability to handle sensitive operations with care and sterility. In production lines for medications or sorting pills, the robots fulfill requirements for hygiene and precision while complying with stringent regulatory standards.

SCARA robots have also made significant inroads into the food industry. They handle tasks ranging from the sorting of raw materials to the packaging of finished products. The food industry demands adherence to strict hygiene standards, which robots can maintain more consistently than human workers. SCARA robots, with their easy-to-clean surfaces, contribute to maintaining hygiene while handling perishable goods.

Fulfillment and logistics operations benefit from SCARA robots through their ability to improve packing and sorting efficiencies. These robots are flexible enough to pick and place items of varying sizes and shapes into packaging, streamlining the distribution process, reducing errors, and speeding up delivery times.

The impact of SCARA robots in laboratory settings and research cannot be overlooked. Precision and repeatability are crucial in these environments, whether in sample preparation or precise measurements. SCARA robots enable laboratories to conduct more experiments with greater accuracy, thereby accelerating the pace of scientific advancement. With the adaptability and precision of SCARA robots, SIENERJI is poised to meet the needs of diverse industries seeking to harness automation for enhanced productivity, quality, and innovation.

Considerations for Implementing SCARA Robots

When implementing SCARA robots in industrial automation, several key considerations should be taken into account to ensure successful integration and maximize efficiency. One crucial factor is the understanding of the specific application requirements and production processes. This involves conducting a thorough analysis to identify the tasks that can be automated using SCARA robots, such as assembly, pick-and-place, packaging, or machine tending. By defining the scope of the tasks, businesses can make informed decisions on the type and number of SCARA robots needed for their operations.

Furthermore, compatibility with existing systems and equipment is another critical consideration. It's essential to assess whether the SCARA robots can seamlessly integrate with the current production environment, including machinery, conveyors, and control systems. Compatibility issues can be mitigated through proper planning and consultation with experienced automation specialists.

Another vital aspect is the selection of the right SCARA robot model based on payload capacity, reach, and speed requirements. Different applications may demand specific robotic capabilities, and choosing the appropriate SCARA robot specifications is essential for achieving optimal performance and productivity.

Moreover, training and safety protocols cannot be overlooked. Adequate training for the workforce responsible for operating and maintaining the SCARA robots is essential to ensure safe and efficient utilization. Additionally, implementing comprehensive safety measures and risk assessments is crucial to safeguard personnel and equipment in the industrial environment.

Case Studies of Successful SCARA Robot Integration

Case Study 1: Automotive Manufacturing

In an automotive production facility, the integration of SCARA robots revolutionized the assembly line processes. By utilizing SCARA robots for precise component placement and fastening tasks, the production cycle time was significantly reduced, leading to a substantial increase in output while maintaining quality standards. The seamless integration of SCARA robots with the existing conveyor systems streamlined the production flow, resulting in enhanced efficiency and cost savings.

Case Study 2: Electronics Assembly

Within an electronics manufacturing plant, the implementation of SCARA robots for PCB (printed circuit board) assembly and soldering operations yielded impressive results. The high-speed and precision capabilities of the SCARA robots improved the accuracy and consistency of soldering processes, leading to a reduction in defects and rework. This integration not only boosted the overall production throughput but also elevated the product quality, thereby positively impacting customer satisfaction.

Future Trends and Innovations in SCARA Robotics

The landscape of industrial automation is in a constant state of evolution, and SCARA robots are at the forefront of this technological revolution. As these robots become more integrated into various industrial processes, emerging trends and innovations shape the capabilities and applications of SCARA robots.