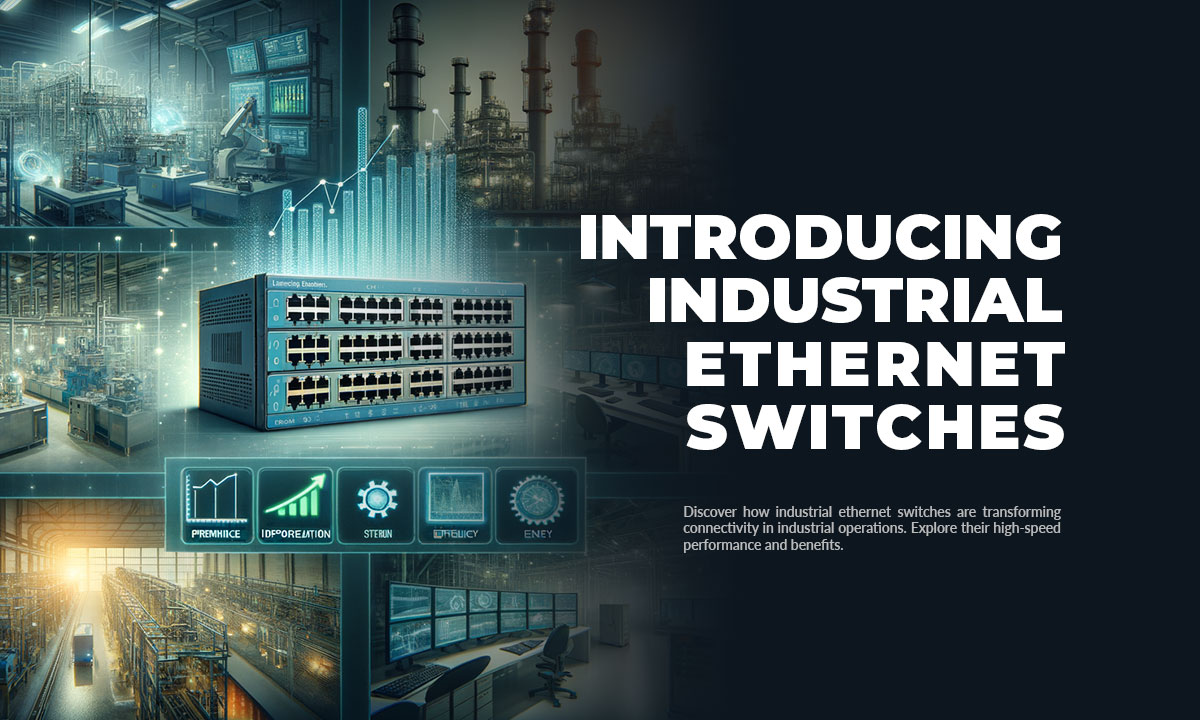

Industrial Ethernet switches are a crucial component in the infrastructure of industrial networking. These specialized switches are designed to withstand the harsh environmental conditions often present in industrial settings, providing reliable and resilient connectivity for mission-critical applications.

Introduction to Industrial Ethernet Switches

Unlike traditional Ethernet switches used in office or commercial environments, industrial Ethernet switches are engineered to deliver high performance and stability in demanding conditions. They are built to withstand wide temperature ranges, vibration, electromagnetic interference, and other challenges commonly encountered in industrial environments. One of the key advantages of industrial Ethernet switches is their ability to prioritize traffic and ensure real-time communication for critical industrial automation applications. These switches support various industrial protocols and enable seamless integration with the Industrial Internet of Things (IIoT) for smart manufacturing and Industry 4.0 initiatives.

The Importance of High-Speed Performance in Industrial Settings

In industrial settings, high-speed performance is a non-negotiable requirement for ensuring efficient and optimized operations. Whether it's manufacturing, process control, transportation systems, or power generation, the ability to transmit data rapidly and reliably is essential for driving productivity and maintaining a competitive edge.

High-speed performance is particularly critical in industrial automation, where real-time control and monitoring of equipment and processes are vital. Industrial Ethernet switches play a pivotal role in facilitating high-speed data transfer, low latency, and deterministic communication, all of which are fundamental for achieving optimal operational efficiency and precision.

With the increasing implementation of advanced technologies such as robotics, machine vision, and AI-driven analytics in industrial environments, the demand for high-speed, low-latency networking solutions has escalated. Industrial Ethernet switches not only meet these demands but also provide the scalability and flexibility required to adapt to evolving industrial requirements.

Moreover, the emphasis on secure and reliable connectivity has become paramount as industrial networks continue to expand. Industrial Ethernet switches with built-in security features offer protection against cyber threats and help maintain the integrity and availability of critical data and control signals.

How Industrial Ethernet Switches Enhance Connectivity

Industrial Ethernet Switches are pivotal in modern industrial environments where the demand for robust, fast, and reliable data communication is incessant. Stepping up to the challenge, these specialized switches unlock high-speed performance and revolutionize connectivity by efficiently managing network traffic. With the increasing amounts of data transmission required for sophisticated industrial applications, these switches maintain an equilibrium between speed and network complexity.

Their ability to support real-time automation and control systems is exemplary. This facilitation of pinpoint timing and synchronized operations across various machinery ensures a seamless and integrated production line. An Industrial Ethernet Switch integrates with a myriad of controllers, sensors, and machines, transcending the limitation of traditional connectivity methods which often buckle under the high demands of throughput and latency.

Additionally, their support for redundant networking is a game-changer in industrial settings, where every moment of downtime can equate to significant financial loss. By implementing redundancy protocols, they provide pathways for network traffic to reroute around failed or compromised paths, ensuring continuous availability and minimizing downtime. The switch's ability to auto-negotiate speed and duplex settings, along with its auto-MDI/MDIX capability, ensures effortless network integration with little to no manual configuration needed.

Furthermore, the rugged design of these switches empowers them to operate under the extreme conditions often found in industrial environments. They are built to endure high levels of vibration, shock, and temperature extremes, guaranteeing a consistently strong and unyielding performance. In essence, Industrial Ethernet Switches function as the backbone of modern industrial connectivity, providing a stable and secure network that bolsters both productivity and efficiency.

Key Features and Benefits of Industrial Ethernet Switches

Industrial Ethernet Switches distinguish themselves from their commercial counterparts through a series of key features specifically tailored for the industrial sector. Durability is one of the foremost features, allowing them to operate in extreme environments. Their solid enclosures and protective coatings make them resistant to dust, chemicals, and water, adhering to the required IP (Ingress Protection) ratings for greater longevity in demanding conditions. Network resilience is yet another important feature. Supporting redundant power inputs, ring, star, and mesh topologies, these switches confer network redundancy and prevent systemic failures. The integration of features like Rapid Spanning Tree Protocol (RSTP) and Industrial Protocols support ensures quick recovery times and seamless data flow, which are crucial for maintaining operational continuity. Energy efficiency rounds out the benefits of Industrial Ethernet Switches. While robust and feature-rich, they are energy-efficient and contribute to reduced operational costs. The switches often feature lower power consumption compared to traditional options, aligning with the growing industrial emphasis on sustainability and reduced carbon footprint.

In conclusion, the combination of hardiness, network resilience, security, management features, efficiency, and cost-effectiveness renders Industrial Ethernet Switches an invaluable asset in enhancing industrial connectivity and unlocking the high-speed performance essential for today's demanding industrial operations.

Applications and Industries That Benefit from Industrial Ethernet Switches

Industrial Ethernet switches play a crucial role in providing reliable and high-speed connectivity for various applications and industries. These switches are designed to withstand harsh industrial environments while ensuring seamless communication and data transfer.In the manufacturing sector, industrial Ethernet switches are essential for enabling real-time communication between various automation devices, such as PLCs, HMIs, and sensors. They support the efficient operation of automated systems, ensuring smooth production processes and minimal downtime.

Transportation and Infrastructure

The transportation industry relies on industrial Ethernet switches to facilitate the networking of traffic management systems, railway infrastructure, and intelligent transportation systems (ITS). These switches ensure constant connectivity and data exchange for reliable and safe transportation operations.

Oil and Gas

In the oil and gas sector, industrial Ethernet switches are utilized for connecting remote monitoring and control systems, SCADA systems, and data acquisition equipment. They provide robust networking solutions for managing critical operations in challenging and remote environments.

Energy and Utilities

Industrial Ethernet switches are instrumental in the energy and utilities industry, supporting the integration of smart grid technologies, substation automation, and energy management systems. They enable the seamless transfer of data for improved power generation and distribution processes.

Considerations for Selecting Industrial Ethernet Switches

When choosing industrial Ethernet switches for specific applications, several key considerations need to be taken into account to ensure optimal performance and reliability:

Environmental Durability

Industrial Ethernet switches should be ruggedly built to withstand extreme temperatures, humidity, vibrations, and electromagnetic interference commonly found in industrial environments. Look for switches with hardened enclosures and industrial-grade components.

Network Traffic and Bandwidth Requirements

Assess the network traffic patterns and bandwidth demands of the intended application. Select switches with sufficient port density, data throughput capabilities, and support for advanced features such as Quality of Service (QoS) and VLAN prioritization.

Reliability and Redundancy

Reliability is paramount in industrial settings. Opt for switches that offer redundant power inputs, support for rapid spanning tree protocol (RSTP), and ring network redundancy to minimize the risk of network disruptions and downtime.

Cybersecurity Features

With the increasing threat of cyber attacks, industrial Ethernet switches should incorporate robust security features such as port-based authentication, access control lists, and data encryption to safeguard critical infrastructure and sensitive data.Integration with Industrial Protocols. Consider the compatibility of the switches with industrial communication protocols such as Modbus TCP, Ethernet/IP, Profinet, and others commonly used in industrial automation and control systems. Seamless integration with these protocols is essential for interoperability.

Management and Monitoring Capabilities

Look for switches that offer comprehensive management interfaces, including web-based management, SNMP support, and diagnostic tools for proactive monitoring of network performance, device status, and firmware updates.

Conclusion: Maximizing Performance with Industrial Ethernet Switches

As the industrial landscape continues to advance with rapid technological evolutions, the importance of robust and reliable connectivity solutions remains critical for maintaining competitive efficiency. In the heart of this transformative journey lies the industrial Ethernet switch, a beacon of high-speed performance that not only revolutionizes connectivity but also unlocks a multitude of operational benefits.

Industrial Ethernet switches are engineered to withstand extreme conditions including temperature fluctuations, vibrations, and electromagnetic interference that would otherwise compromise conventional office networking equipment. These switches are central to creating a resilient industrial network that can sustain consistent uptime and provide the backbone for connected devices and systems. The high-speed transfer capabilities of industrial Ethernet switches ensure that data-driven decisions are made in real time, optimizing processes, boosting productivity, and enabling predictive maintenance strategies.

The deployment of industrial Ethernet switches leads to enhanced communication protocols that are vital for the integration