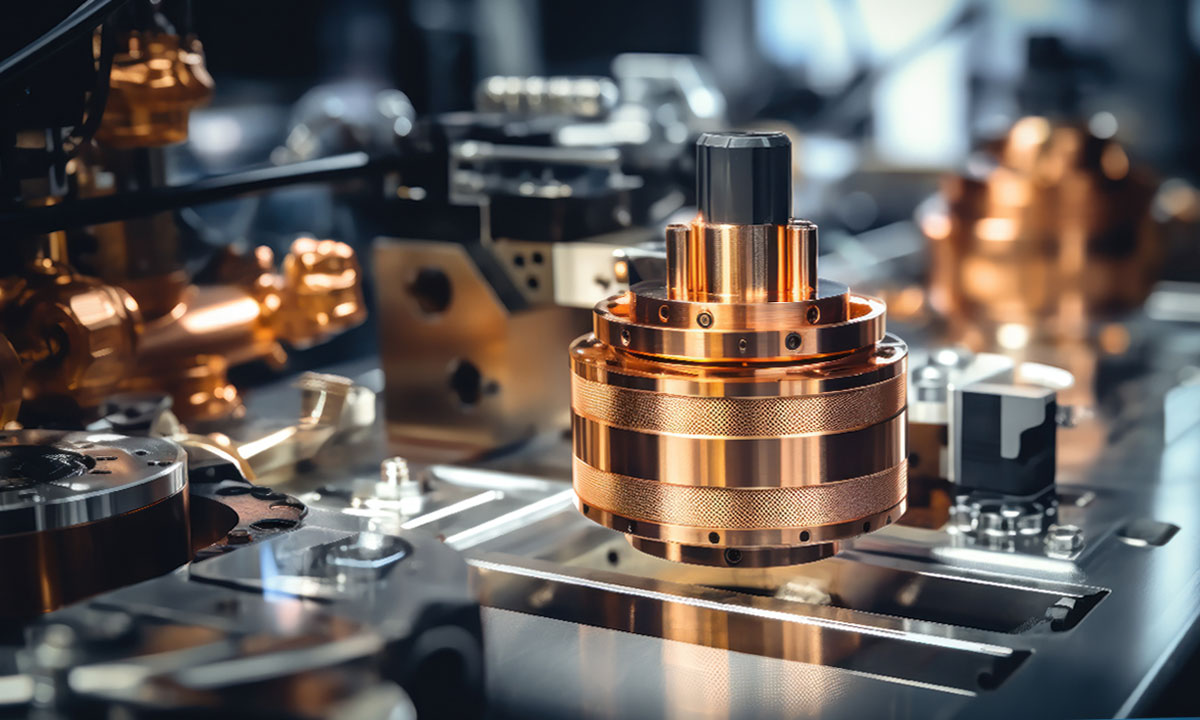

Welcome to our comprehensive guide on AC motors! If you've ever wondered about the inner workings of these essential components in various electrical systems, you're in for a treat. In this blog post, we'll delve into the fascinating world of AC motors, exploring their different types and applications.

From induction motors to synchronous motors and everything in between, we'll cover it all. So buckle up and join us on this electrifying journey through the realm of AC motors!

Exploring the Different Types of AC Motors: Which One is Right for You?

AC motors come in various types, each with its unique characteristics and applications. Understanding the differences between induction motors, synchronous motors, and other variations is essential for choosing the right one to suit your specific needs.

Introduction

Welcome to our exploration of AC motors. In this blog post, we will delve into the different types of AC motors and help you understand which one may be right for your needs. Let's begin by taking a closer look at the fascinating world of AC motors.

Overview of AC Motors

AC motors, or alternating current motors, are essential components in various electrical systems. They convert electrical energy into mechanical energy through the interaction of magnetic fields. These motors play a crucial role in powering a wide range of devices and machinery across different industries.

Operating Principles

AC motors operate based on the principles of electromagnetic induction, where a changing magnetic field induces an electric current in conductors. This phenomenon allows for the conversion of electrical energy into mechanical motion, making AC motors essential components in various applications across industries.

Understanding the basics

AC motors are devices that convert electrical energy into mechanical energy through the interaction of magnetic fields. The fundamental principle behind AC motors is electromagnetic induction, where a changing magnetic field induces current flow in conductors, resulting in rotational motion. Understanding this basic concept is crucial for grasping the operation of AC motors.

History

The history of AC motors dates back to the late 19th century when Nikola Tesla and others pioneered the development of alternating current systems. Their work laid the foundation for the evolution of various types of AC motors that are widely used today in industrial, commercial, and residential applications.

Evolution of AC motors

The evolution of AC motors has been marked by significant advancements over the years. From the early developments in induction motors to the emergence of various specialized types, such as synchronous and servo motors, the progression in technology has led to a wide range of applications across industries.

Induction Motor

The induction motor is a widely used type of AC motor known for its simplicity and reliability. It operates on the principle of electromagnetic induction, where the rotating magnetic field induces currents in the rotor to produce motion. This technology has been instrumental in powering various industrial and commercial applications.

In-depth look at induction motors

Induction motors are the workhorses of the industry, widely used due to their robustness and reliability. These motors operate on the principle of electromagnetic induction, where a rotating magnetic field induces currents in the rotor conductors, producing motion without direct electrical connections.

Synchronous Motor

Synchronous motors operate at a fixed speed determined by the frequency of the electrical supply. They maintain synchronous speed with the rotating magnetic field, making them ideal for applications requiring precise control and constant speed operation.

Exploring synchronous motors

Synchronous motors are designed to operate at a constant speed determined by the frequency of the applied voltage. These motors have rotor windings that receive direct current, creating a magnetic field which synchronizes with the rotating magnetic field of the stator. This synchronization allows for efficient performance in various industrial applications.

Other AC Motor Types

There are various other types of AC motors beyond induction and synchronous motors, each serving specific needs. These include slip, polyphase cage rotor, wound rotor, two-phase servo motor, single-phase induction motor, and more. Each type has unique characteristics and applications in different industries.

Different variations and applications

AC motors come in various types suited for different applications. From slip and polyphase cage rotor to universal and repulsion motors, each serves specific functions based on their design and operating principles. Understanding these variations can help in choosing the right motor for a particular task.

Slip

Slip in AC motors refers to the difference between synchronous speed and actual rotor speed. It is crucial for motor efficiency, as slip allows the induction motor to produce torque. Understanding slip helps in optimizing motor performance for various applications.

Polyphase cage rotor

The polyphase cage rotor is a common type of AC motor rotor that consists of conducting bars arranged in a cage-like structure. When energized, the rotating magnetic field induces currents in the bars, generating torque. This design offers simplicity and ruggedness, making it suitable for various industrial applications.

Polyphase wound rotor

Polyphase wound rotor AC motors are known for their ability to handle variable speed applications by connecting external resistors. The rotor windings allow for improved control and efficiency in industrial settings where precise speed regulation is required.

Two-phase servo motor

The two-phase servo motor is a specialized AC motor used for precise control in applications such as robotics and automation. It operates using two phases of alternating current to produce smooth and accurate movements, making it ideal for tasks requiring high precision and responsiveness.

Single-phase induction motor

Single-phase induction motors are commonly used in household appliances due to their simple design and cost-effectiveness. These motors operate on a single phase AC power supply, making them suitable for applications where three-phase power is not available.

Polyphase synchronous motor

The polyphase synchronous motor operates on the principle of creating a rotating magnetic field. By synchronizing with the frequency of the applied voltage, this type of motor offers precise speed control and is commonly used in applications requiring constant speeds such as industrial machinery and conveyor belts.

Single-phase synchronous motor

Single-phase synchronous motors operate on the same principles as polyphase synchronous motors but are designed for single-phase power systems. These motors provide constant speed and are commonly used in applications where precise speed control is required, such as timing devices and clocks.

Hysteresis synchronous motor

The Hysteresis Synchronous Motor operates on the principle of hysteresis, where the rotor maintains a constant magnetic alignment with the rotating magnetic field. This type of motor is known for its precise speed control and low maintenance requirements due to its simple construction.

Universal motor and series wound motor

Universal motors are versatile, able to operate on both AC and DC power sources. They find common use in household appliances due to their compact size and high speed capabilities. Series wound motors have a simple design with the field winding connected in series with the armature windings for high torque applications.

Repulsion motor

The repulsion motor is a type of AC motor that features brushes and a wound rotor. It operates on the principle of repulsion between like magnetic poles, leading to rotation. This design allows for variable speed control, making it suitable for applications requiring adjustable speeds.

Exterior rotor

The exterior rotor AC motor is a unique design where the rotor is located on the outside of the stator. This configuration offers advantages in terms of heat dissipation and efficiency, making it suitable for certain specialized applications requiring high torque output.

Sliding rotor motor

The sliding rotor motor is a type of AC motor where the rotor can move axially to adjust the speed and torque. This design allows for better control and efficiency in various industrial applications.

Electronically commutated motor

The Electronically Commutated Motor (ECM) is a type of AC motor that uses electronic controls for commutation instead of traditional mechanical brushes. This technology allows for improved efficiency and precise control of the motor's speed and torque, making it ideal for applications where energy savings and variable speed operation are essential.

Watthour-meter motor

The Watthour-meter motor is a specialized AC motor commonly used in electricity metering applications. It operates based on the principles of energy consumption measurement, providing accurate readings for billing purposes. This type of motor plays a crucial role in monitoring and managing electrical usage efficiently.

Slow-speed synchronous timing motor

The Slow-speed synchronous timing motor is a specialized type of AC motor designed for applications requiring precise and constant speed control. Operating at lower speeds, this motor ensures accurate timing in various industrial processes and equipment.

Conclusion

Choosing the right AC motor for your specific needs requires careful consideration of various factors. It is essential to assess your requirements, budget constraints, and desired performance characteristics before making a decision. Conduct thorough research and seek expert advice to ensure you select the most suitable AC motor for your application.

Choosing the right AC motor for your needs

Choosing the right AC motor for your needs requires careful consideration of various factors such as power requirements, speed control, efficiency, and cost. It is essential to assess your specific application and understand the operating principles of different types of AC motors to make an informed decision.

Induction motors are widely used for their simplicity and reliability in applications where precise speed control is not critical. On the other hand, synchronous motors offer better efficiency and power factor correction but may require additional control mechanisms.

Other variations like slip ring motors, universal motors, repulsion motors, or electronically commutated motors each have unique characteristics suited for specific applications ranging from industrial machinery to household appliances.

By evaluating your requirements against the capabilities of different AC motor types, you can select the most suitable option that aligns with your performance expectations and budget constraints. Consulting with a professional engineer or motor specialist can also provide valuable insights into making a well-informed choice tailored to your specific needs.

Choosing the right AC motor involves finding a balance between performance parameters, operational demands, and cost considerations to ensure optimal functionality and longevity in your application.