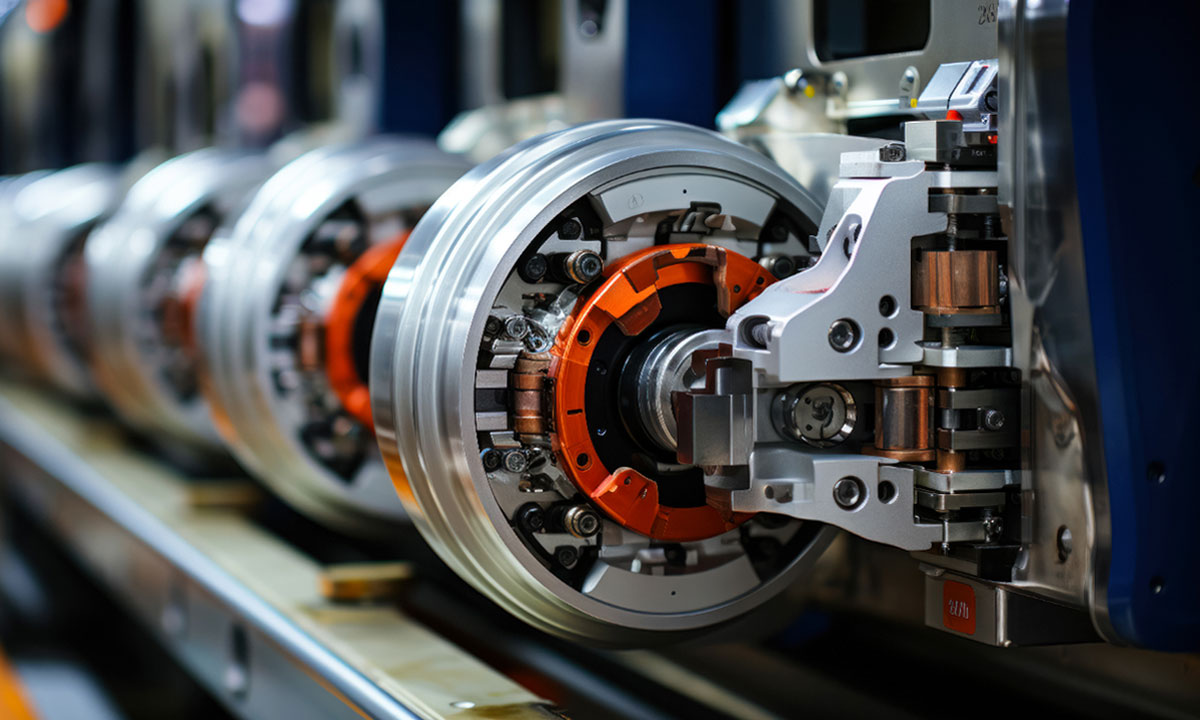

Welcome to the Ultimate Guide to Understanding DC Servo Motors. In this comprehensive exploration, we delve into the intricate world of servo motors, focusing specifically on the dynamic realm of DC servo motors.

These essential components play a crucial role in numerous industries, powering precision machinery with unparalleled accuracy and control. Join us on a journey through the fundamentals, applications, history, types, advantages, and maintenance of DC servo motors as we unravel their significance in modern engineering and automation systems.

The Ultimate Guide to Understanding DC Servo Motors

DC servo motors are sophisticated devices that provide precise control over speed and position in various applications. Understanding the intricacies of these motors is essential for engineers and technicians working in industries such as robotics, aerospace, manufacturing, and more. By delving into the workings of DC servo motors, one can unlock their potential to drive efficiency and accuracy in automated systems.

Introduction

Servo motors are essential components in various industries, offering precise control over motion. Among the different types of servo motors available, DC servo motors stand out for their efficiency and reliability. Understanding how these motors work is crucial for engineers and technicians working with automation systems.

DC servo motors utilize direct current to power the motor's rotation, providing accurate positioning and speed control. These motors play a vital role in robotics, CNC machines, aerospace applications, and more due to their high performance capabilities.

Understanding Different Types of Servo Motors

Servo motors are essential components in various industries, known for their precise control and accuracy. Understanding the different types of servo motors is crucial for selecting the right one for specific applications.

Two common types include DC servo motors and AC servo motors. DC servo motors operate using direct current, offering high torque at low speeds, while AC servo motors use alternating current for better efficiency and higher speeds. Each type has its unique characteristics and suitability based on the application requirements.

DC Servo Motors

DC servo motors are a type of motor commonly used in industrial automation systems. They operate using direct current (DC) power and provide precise control over speed, position, and acceleration. These motors are equipped with feedback mechanisms such as encoders or resolvers to ensure accurate positioning and movement.

DC servo motors offer high efficiency and dynamic response, making them ideal for applications that require quick and precise motion control. They are widely used in robotics, CNC machines, conveyor systems, and other equipment where precision is crucial.

AC Servo Motors

AC servo motors are another type of motor commonly used in industrial applications. Unlike DC servo motors, AC servo motors operate on alternating current power sources. These motors offer precise control over speed and position, making them ideal for tasks requiring high accuracy. AC servo motors utilize feedback systems to maintain the desired performance levels, ensuring stable and efficient operation.

One key advantage of AC servo motors is their ability to provide high torque at low speeds, making them suitable for heavy-duty applications. Additionally, these motors tend to be more durable and require less maintenance compared to other types of motors.

Exploring Servo Motor Applications

Servo motors find extensive applications in various industries due to their precise control and accuracy. They are commonly used in robotics, manufacturing automation, CNC machines, and automotive systems. In robotics, servo motors play a crucial role in controlling the movement of robotic arms with high precision and repeatability.

In manufacturing automation, servo motors drive conveyor belts, packaging machines, and assembly lines efficiently. CNC machines rely on servo motors for accurate positioning of cutting tools during machining processes. Additionally, servo motors enhance the performance of automotive systems such as electric power steering and throttle control mechanisms.

Servo Motors vs. Stepper Motors

Servo motors and stepper motors are both popular choices for precision motion control applications. While servo motors use feedback to adjust their position accurately, stepper motors move in discrete steps without the need for feedback.

Servo motors offer faster speeds and higher torque capabilities compared to stepper motors, making them ideal for dynamic and high-performance tasks. On the other hand, stepper motors are cost-effective and simpler to control, suitable for applications requiring precise positioning within a limited budget.

Control Mechanism

Servo motors utilize a control mechanism to precisely regulate the position, speed, and acceleration of the motor shaft. This control mechanism typically involves a feedback system that continuously monitors the actual motion and compares it to the desired output. By adjusting voltage levels or pulse width modulation signals based on this feedback, servo motors can accurately follow set commands without overshooting or lagging.

The control mechanism in DC servo motors plays a critical role in maintaining stability and accuracy during operation. It ensures that the motor responds promptly to changes in input signals, allowing for smooth and precise movement in various applications requiring controlled motion.

Torque and Speed

DC servo motors are known for their ability to provide precise control over torque and speed. Torque refers to the rotational force produced by the motor, while speed indicates how quickly the motor can rotate. In servo systems, torque and speed are crucial factors that determine the performance and efficiency of the motor in various applications.

The relationship between torque and speed is inversely proportional - as one increases, the other decreases. This trade-off must be carefully balanced in DC servo motors to ensure optimal performance. By understanding these dynamics, engineers can design systems that meet specific requirements for different tasks effectively.

Cost Comparison

When comparing DC servo motors, cost is a crucial factor to consider. DC servo motors typically come at a higher price point compared to stepper motors due to their advanced control systems and precision. The initial investment in a DC servo motor may be higher, but the long-term benefits of enhanced performance and accuracy often outweigh the upfront cost.

Additionally, maintenance costs should also be factored into the overall cost comparison between different types of motors. While DC servo motors may require more specialized care and attention, their reliability and efficiency can result in lower operational expenses over time.

History and Evolution of Servo Motors

Servo motors have a rich history dating back to the mid-19th century when James Clerk Maxwell first proposed the concept of a feedback control system. The evolution of servo motors accelerated in the 20th century with advancements in electronics and control theory, leading to their widespread adoption across industries.

In the 21st century, servo motors continue to evolve with improvements in precision, efficiency, and integration with digital technologies. From their humble beginnings as part of early automation systems to now being integral components in robotics and industrial machinery, servo motors have come a long way in shaping modern automation processes.

Types and Variations of DC Servo Motors

DC servo motors come in various types and variations, each designed to meet specific performance requirements. The AKM2G Servo Motor is known for its high power density and precise control capabilities, making it ideal for industrial applications requiring precision and efficiency.

Another popular choice is the AKMA Servo Motors, known for their compact design and high torque output. These motors are commonly used in robotics, automation systems, and other applications where space constraints are a concern. Additionally, the Kollmorgen Goldline® Series Servo Motors offer exceptional reliability and performance in demanding environments.

AKM2G Servo Motor

The AKM2G Servo Motor is a cutting-edge technology developed by Kollmorgen, designed to provide high performance and precision in various industrial applications. Known for its exceptional torque density and speed capabilities, the AKM2G offers superior efficiency and dynamic response. With advanced features such as single-cable technology and feedback options, this servo motor stands out as a reliable choice for demanding motion control systems.

Equipped with innovative design elements like optimized electromagnetic circuitry and low inertia rotor options, the AKM2G servo motor ensures smooth operation and precise positioning accuracy. Its compact size and easy integration make it an ideal solution for industries requiring agile motion control solutions.

AKMA Servo Motors

The AKMA Servo Motors are known for their high performance and reliability in industrial applications. These motors offer precise control over speed and position, making them ideal for tasks that require accuracy and consistency. With advanced technology and robust construction, the AKMA Servo Motors deliver exceptional torque output to meet the demands of various automation systems.

Designed to withstand harsh operating conditions, the AKMA Servo Motors ensure smooth operation and long-term durability. Equipped with efficient cooling systems and innovative features, these motors provide optimal performance in demanding environments.

AKM Low Voltage DC Servo Motors

AKM Low Voltage DC Servo Motors are known for their efficiency and reliability in various industrial applications. These motors offer precise control over speed and position, making them ideal for tasks that require high accuracy. With their compact design and low voltage requirements, AKM Low Voltage DC Servo Motors are versatile enough to be used in robotics, automation systems, and other motion control applications.

The advanced technology incorporated into AKM Low Voltage DC Servo Motors ensures smooth operation and consistent performance even under heavy loads. Their ability to deliver high torque at low speeds makes them a popular choice among engineers looking for a dependable solution for motion control challenges.

Kollmorgen Goldline® Series Servo Motors

The Kollmorgen Goldline® Series Servo Motors are renowned for their high performance and precision control capabilities. These servo motors offer exceptional torque density, making them ideal for applications requiring dynamic responsiveness and accuracy. With a wide range of sizes and options available, the Goldline® Series can meet the diverse needs of various industries.

Equipped with advanced feedback devices and rugged construction, these servo motors deliver reliable operation in demanding environments. Whether used in robotics, packaging machinery, or aerospace systems, the Kollmorgen Goldline® Series consistently delivers superior performance and efficiency.

EKM Series Servo Motors

The EKM Series Servo Motors are renowned for their high performance and precision in industrial applications. With advanced design and technology, these motors offer exceptional torque density and efficiency, making them ideal for demanding motion control requirements. The EKM Series is known for its reliability, accuracy, and durability, providing seamless operation in various automation processes.

These servo motors are designed to deliver precise positioning control with low inertia and high dynamic response. The EKM Series stands out for its compact size without compromising on power output, ensuring optimal performance in a wide range of industries such as manufacturing, robotics, and packaging.

Advantages and Disadvantages of DC Servo Motors

DC servo motors offer precise control over speed and position, making them ideal for applications requiring high accuracy and responsiveness. They provide better efficiency compared to stepper motors, leading to energy savings in the long run. Additionally, DC servo motors can handle higher speeds and deliver smoother operation, enhancing overall performance.

However, one drawback of DC servo motors is their higher initial cost compared to other types of motors. Maintenance and tuning requirements are also more complex, requiring specialized knowledge for optimal performance. Despite these disadvantages, the advantages of DC servo motors often outweigh the drawbacks in many industrial applications.

Support and Maintenance for DC Servo Motors

Support and maintenance for DC servo motors are crucial to ensure optimal performance. Regular inspection of the motor components, such as brushes and bearings, is essential to prevent potential breakdowns. Additionally, proper lubrication and cleaning of the motor can extend its lifespan and efficiency.

Moreover, monitoring the motor's temperature and voltage levels can help detect any abnormalities early on. It is recommended to follow manufacturer guidelines for servicing intervals and procedures to keep the DC servo motor running smoothly.

Conclusion

DC servo motors are a crucial component in various industries and applications due to their precision, accuracy, and efficiency. Understanding the different types of servo motors, such as DC and AC servo motors, exploring their applications, comparing them with stepper motors based on control mechanisms, torque-speed characteristics, and cost considerations can provide valuable insights for selecting the right motor for specific needs.

The history and evolution of servo motors have seen significant advancements in technology leading to more sophisticated and reliable systems. Variations of DC servo motors like AKM2G Servo Motor, AKMA Servo Motors, AKM Low Voltage DC Servo Motors from Kollmorgen Goldline® Series to EKM Series offer diverse options catering to different requirements.

Despite their advantages in providing precise control over speed and position while maintaining high torque output levels, DC servo motors also come with certain limitations that need to be addressed. Proper support and maintenance practices play a crucial role in ensuring optimal performance and longevity of these motor systems.

A comprehensive understanding of DC servo motors along with proper selection criteria based on application-specific requirements is essential for harnessing the full potential of these advanced motion control devices.