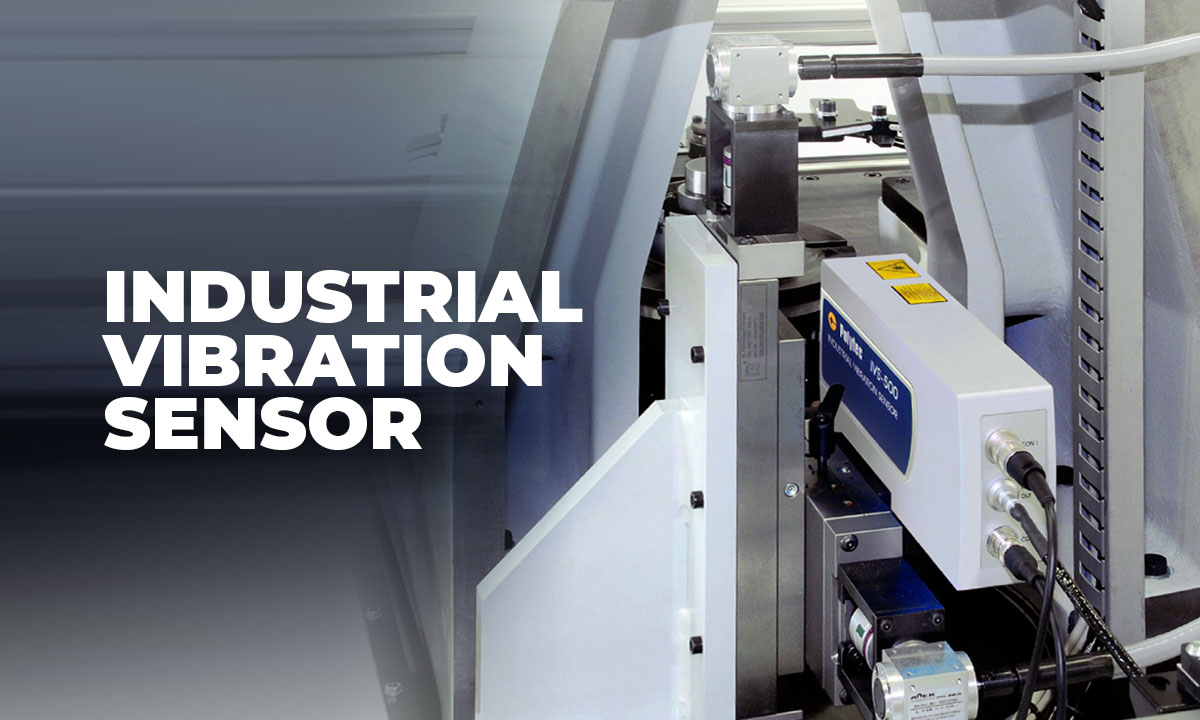

Vibration sensors, also known as accelerometers, are devices designed to measure and monitor the vibration levels in industrial machinery and equipment. They detect variations in acceleration, velocity, and displacement of an object or system.

Understanding Vibration Sensors

By understanding the vibration patterns, engineers and maintenance teams can identify potential issues such as misalignment, imbalance, or bearing wear in rotating machinery. These sensors play a crucial role in predictive maintenance, helping to prevent unexpected downtime and reduce maintenance costs by enabling timely intervention before a critical failure occurs. By continuously monitoring the vibrations, industrial professionals gain insights into the overall health and performance of the equipment, allowing them to schedule maintenance activities more effectively.

Types of Vibration Sensors

- Piezoelectric Sensors: These sensors generate an electrical charge when subjected to mechanical stress, such as vibration. They are highly sensitive and capable of measuring high-frequency vibrations, making them suitable for detecting faults in rotating equipment.

- Capacitive Sensors: Capacitive vibration sensors measure changes in capacitance caused by the displacement of a diaphragm due to vibration. They are suitable for lower-frequency vibration monitoring and can offer high resolution in measuring the amplitude of vibrations.

- Piezoresistive Sensors: These sensors change their electrical resistance in response to mechanical stress, like vibration. They are commonly used for measuring dynamic strain, shock, and vibration. Piezoresistive sensors are suitable for a wide range of industrial applications due to their durability and ruggedness.

- Strain Gauge Sensors: Strain gauge sensors measure the strain on an object subjected to vibration. They are often bonded to the surface of the vibrating component and are capable of monitoring low-frequency vibrations with high precision. Understanding the different types of vibration sensors and their capabilities is essential for selecting the most appropriate sensor for specific industrial applications. Each type has its own advantages and limitations, and choosing the right sensor is crucial for accurate vibration monitoring and predictive maintenance.

Considerations for Choosing a Vibration Sensor

When tasked with selecting the right vibration sensor for your industrial applications, several critical considerations come into play to ensure optimal performance and longevity. Industrial professionals and maintenance teams know that the first step involves a clear understanding of the equipment's operating conditions. Temperature extremes, moisture, dust, and hazardous locations are all environmental factors that can impact the sensor's efficacy.

A primary consideration is the type of vibration you aim to monitor. Is it for predictive maintenance or for protecting critical equipment from catastrophic failure? This will determine whether you need a high-sensitivity sensor for low-level vibrations or a robust sensor for detecting significant anomalies. Additionally, the physical characteristics of your machinery, such as size, configuration, and accessibility, will influence the mounting style and location of the sensor.

Also consider the measurement range and frequency required for your specific application. Sensors come with various ranges and sensitivities, and it's essential to match these to the expected vibration amplitude and frequency of your equipment. Misalignment in these parameters could lead to inaccurate measurements or even missed detection.

Another key consideration is the output type of the vibration sensor. Depending on your monitoring system, you may require a sensor with a 4-20mA output, a digital output like PLC, or even wireless capabilities for remote monitoring. The connectivity should align with your existing systems to integrate seamlessly into your operation without extensive modifications.

Finally, factor in the total cost of ownership, which goes beyond the initial purchase price. Consider installation costs, maintenance requirements, and the durability of the sensor to assess its value over its lifespan. Choosing a sensor from a trusted provider like SIENERJI ensures you are investing in quality and reliability, ultimately contributing to reduced downtime and maintenance costs.

Key Features to Look for in a Vibration Sensor

In the selection of a vibration sensor, several key features stand out that can make a significant difference in the performance of your monitoring solution. The sensitivity of the sensor is paramount. This should be closely correlatable to the expected vibration levels of your machines to ensure accurate detection and analysis of data.

Frequency range is another vital attribute, as different applications generate vibrations at various frequencies. The chosen sensor should cover the full range of frequencies your application may encounter. Broadband sensors that cover a wide frequency spectrum offer versatility but may need to be paired with more specialized sensors for detailed analysis in specific frequency bands.

Temperature range is also critical. The sensor must withstand the operational temperature ranges of your industrial environment, which may include extreme heat or cold. Sensors rated for these extremes will provide consistent performance without the risk of temperature-induced inaccuracies or failures.

Furthermore, the durability and build quality of the vibration sensor are non-negotiables for industrial settings. Look for robust construction that can handle the rigors of daily operation, including resistance to shock, corrosion, and ingress of contaminants. Some sensors also need to meet specific standards or certifications, like ATEX or IECEx, indicating suitability for use in hazardous or explosive environments.

Another desirable feature is the ease of integration with existing data collection and analysis systems. The sensor should be compatible with monitoring equipment and software platforms, enabling a smooth transfer of data for immediate analysis and decision-making. Depending on the application, the sensor's output signal should be clear and unambiguous, minimizing the chance for error in processing the data.

To further harness the potential of modern technology, advanced features such as onboard processing and wireless communication can enhance the functionality of a vibration sensor. These features facilitate real-time analysis and allow for remote monitoring, which is particularly beneficial for sites that are challenging to access or for equipment that requires constant surveillance.

Selecting a vibration sensor with the right combination of these key features will contribute significantly to the reliability and efficiency of your vibration monitoring system. SIENERJI, with its extensive portfolio, offers options that meet the highest standards in all of these areas, ensuring that your operations are safeguarded against unforeseen equipment failures and costly downtime.

Installation and Maintenance of Vibration Sensors

When it comes to installing vibration sensors, the first step is to carefully select the mounting location to ensure it represents the overall equipment vibration. The sensor should be securely mounted to minimize any potential movement or vibrations from the mounting surface. Proper cabling and connections are crucial to ensure accurate signal transmission without interference.

Regular maintenance of vibration sensors is essential to ensure their continued accuracy and reliability. This includes periodic calibration to maintain precision. Additionally, inspecting the sensor for any physical damage, corrosion, or wear is important. Proper maintenance not only extends the lifespan of the sensor but also ensures the ongoing safety and efficiency of the equipment it monitors.

Applications and Industries Implementing Vibration Sensors

Vibration sensors find wide-ranging applications across various industries. In the manufacturing sector, these sensors are crucial for monitoring the condition of machinery, detecting potential faults, and predicting maintenance requirements. The automotive industry utilizes vibration sensors for engine condition monitoring, while the aerospace industry uses them for structural health monitoring of aircraft components.

Industries such as oil and gas, power generation, and mining rely on vibration sensors to monitor the health and performance of critical equipment, including pumps, turbines, and compressors. In the construction industry, these sensors are used for structural health monitoring of buildings and bridges. Moreover, vibration sensors play a vital role in predictive maintenance strategies, helping industries avoid costly downtime and unexpected failures.

Conclusion: Importance of Choosing the Right Vibration Sensor for Industrial Operations

When it comes to maintaining the health and functionality of industrial machinery, the implementation of a suitable vibration sensor cannot be overstated. At SIENERJI, we recognize the substantial benefits that a meticulously selected vibration sensor brings to the table. It’s not just about safeguarding equipment; it’s about optimizing performance, enhancing safety, and ultimately protecting a company's bottom line.

Choosing the right vibration sensor is a strategic decision that hinges on understanding the types of vibrations your machinery emits and the environmental conditions they operate in. A well-chosen sensor ensures that maintenance teams receive timely and accurate data, enabling them to predict potential equipment failures before they occur. This proactive approach to maintenance can save businesses from unexpected downtime, which is often accompanied by significant financial and productivity losses.

Moreover, with the right vibration sensor in place, engineers and maintenance teams can extend the lifespan of vital industrial assets. Constant monitoring allows for the early detection of irregular patterns, allowing for timely adjustments or repairs. In essence, a vibration sensor serves as the eyes and ears within complex machinery, signaling the need for attention when needed most.

The interconnected nature of industries today demands that equipment operates at peak efficiency, and vibration sensors play a pivotal role in ensuring this. For example, in automated production lines, a minor misalignment can cascade into a major production hicane. Therefore, the reliability and accuracy of the chosen vibration sensor directly influence the smooth functioning of such critical systems.

Our expertise at SIENERJI lies in matching industrial professionals with the most appropriate sensors for their unique requirements. Recognizing that each application may have its specific demands, we maintain a repository of diverse sensors, each designed to provide the most beneficial outcomes. Whether it's a high-sensitivity sensor for minute vibrations or a robust sensor for harsh environments, we provide solutions that extend beyond mere products—they are integral components of a comprehensive industrial strategy.

The importance of choosing the right vibration comprehension and integration of this tool into industrial operations cannot be understated. With performance, safety, and cost-efficiency at stake, it’s an investment that continues to justify its worth in an ever-evolving industrial landscape.

Understanding Vibration Sensors Vibration sensors are crucial components in industrial settings, as they help detect and monitor the vibration levels of machinery and equipment. Understanding the different types of vibration sensors is essential for making an informed decision. There are various types of vibration sensors such as velocity sensors, accelerometer sensors, and proximity probes.

Each type has its unique features and applications, so it's vital to assess the specific needs of your equipment before selecting a sensor. Considerations for Industrial Applications When choosing a vibration sensor for industrial applications, several key factors should be taken into account. Firstly, consider the operating environment and conditions in which the sensor will be deployed. Factors such as temperature, humidity, and exposure to dust or chemicals can impact the sensor's performance. Additionally, the frequency range of the vibration to be measured plays a crucial role in selecting the right sensor.

Furthermore, the installation and maintenance requirements should align with the available resources and expertise within your organization. Evaluating Sensor Performance The performance of a vibration sensor is a critical consideration. Factors such as sensitivity, frequency range, accuracy, and reliability are essential aspects to evaluate when selecting a vibration sensor. It's important to choose a sensor that provides accurate and reliable data to effectively monitor the machinery's health and performance. Additionally, consider the signal conditioning and output options that best suit your monitoring and analysis systems.

Choosing the Right Vibration Sensor for Your Needs After carefully considering the technical specifications and requirements, it's time to select the vibration sensor that best fits your needs. Consult with experts or suppliers to ensure that the chosen sensor meets the specific demands of your industrial equipment. Make sure to inquire about compatibility with existing monitoring systems and the availability of technical support.

Conclusion Choosing the right vibration sensor is crucial for ensuring the smooth operation of industrial machinery and equipment. By understanding the various types of sensors, considering industrial application requirements, evaluating sensor performance, and seeking expert advice, you can make an informed decision that aligns with your specific needs and maximizes the efficiency of your operations.